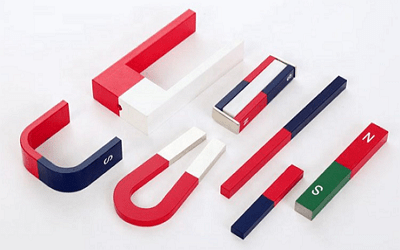

permanent magnet

AlNiCo Magnet

Aluminum Nickel Cobalt Magnet

Magnetic Properties

Sintered AlNiCo Magnets

| Grade | Br | Hcb | (BH)max | Tc | Tw | Code | |||

|---|---|---|---|---|---|---|---|---|---|

| mT | Gs | kA/M | Oe | kJ/m³ | MGOe | ℃ | ℃ | ||

| LN10 | 600 | 6000 | 40 | 500 | 10 | 1.2 | 750 | 550 | AlNiCo3 |

| LNG12 | 700 | 7000 | 44 | 550 | 12 | 1.5 | 750 | 550 | AlNiCo2 |

| LNG13 | 680 | 6800 | 48 | 600 | 13 | 1.63 | 800~850 | 550 | |

| LNG18 | 900 | 9000 | 48 | 600 | 18 | 2.25 | 800~850 | 550 | AlNiCo4 |

| LNG37 | 1200 | 12000 | 48 | 600 | 37 | 4.63 | 800~850 | 550 | AlNiCo5 |

| LNG40 | 1250 | 12500 | 48 | 600 | 40 | 5 | 800~850 | 550 | |

| LNG44 | 1250 | 12500 | 52 | 650 | 44 | 5.5 | 800~850 | 550 | |

| LNG52 | 1300 | 13000 | 56 | 700 | 52 | 6.5 | 800~850 | 550 | AlNiCo5DG |

| LNG56 | 1300 | 13000 | 58 | 720 | 56 | 7 | 800~850 | 550 | |

| LNG60 | 1330 | 13300 | 60 | 750 | 60 | 7.5 | 800~850 | 550 | AlNiCo5-7 |

| LNGT18 | 580 | 5800 | 90 | 1130 | 18 | 2.25 | 800~850 | 550 | AlNiCo7 |

| LNGT28 | 1000 | 10000 | 56 | 700 | 28 | 3.5 | 800~850 | 550 | AlNiCo6 |

| LNGT30 | 1100 | 11000 | 56 | 700 | 30 | 3.75 | 800~850 | 550 | AlNiCo6 |

| LNGT32 | 800 | 8000 | 100 | 1250 | 32 | 4 | 800~850 | 550 | AlNiCo8 |

| LNGT38 | 800 | 8000 | 110 | 1380 | 38 | 4.75 | 800~850 | 550 | |

| LNGT44 | 850 | 8500 | 120 | 1500 | 44 | 5.5 | 800~850 | 550 | |

| LNGT48 | 900 | 9000 | 120 | 1500 | 48 | 6 | 800~850 | 550 | |

| LNGT60 | 950 | 9500 | 110 | 1380 | 60 | 7.5 | 800~850 | 550 | |

| LNGT72 | 1050 | 10500 | 112 | 1500 | 72 | 9 | 800~850 | 550 | AlNiCo9 |

| LNGT88 | 1100 | 11000 | 115 | 1450 | 88 | 11 | 800~850 | 550 | |

| LNGT96 | 1150 | 11500 | 118 | 1480 | 96 | 12 | 800~850 | 550 | |

| LNGT36J | 700 | 7000 | 140 | 1750 | 36 | 4.5 | 800~850 | 550 | AlNiCo8HC |

| LNGT48J | 800 | 8000 | 145 | 1820 | 48 | 6 | 800~850 | 550 | AlNiCo8HC |

| LNGT52J | 850 | 8500 | 140 | 1750 | 52 | 6.5 | 800~850 | 550 | AlNiCo8HC |

The sintered AlNiCo magnet boasts slightly inferior magnetic properties, yet exhibits superior mechanical properties compared to cast AlNiCo materials. Particularly in smaller sizes, the sintered AlNiCo magnet emerges as the optimal choice. The sintering process also proves adept at large-scale production, resulting in parts that possess an enhanced structural strength compared to their cast counterparts. Precise tolerances can be achieved without the need for grinding.

Cast Alnico Magnets

Cast AlNiCo 5 is the most commonly used form of cast AlNiCo magnets. It exhibits superior magnetic properties, with a high energy product of 5 MGOe or more. As a result, it finds extensive application in a variety of rotating machinery, communication systems, meters and instruments, sensors, and holding mechanisms. AlNiCo 8, with its increased cobalt content of up to 35%, demonstrates enhanced resistance to demagnetization, making this particular material particularly effective in applications involving short lengths or length-to-diameter ratios of less than 2:1.

Temperature Characteristics

Application

Alnico permanent magnets are utilized across a variety of industries where magnetic stability and performance are critical. Notably, they serve as foundational materials in key sectors such as aerospace, defense, telecommunications, medical instruments, and electric motors, where demanding operating conditions require the exceptional magnetism and reliability provided by Alnico magnets.