permanent magnet

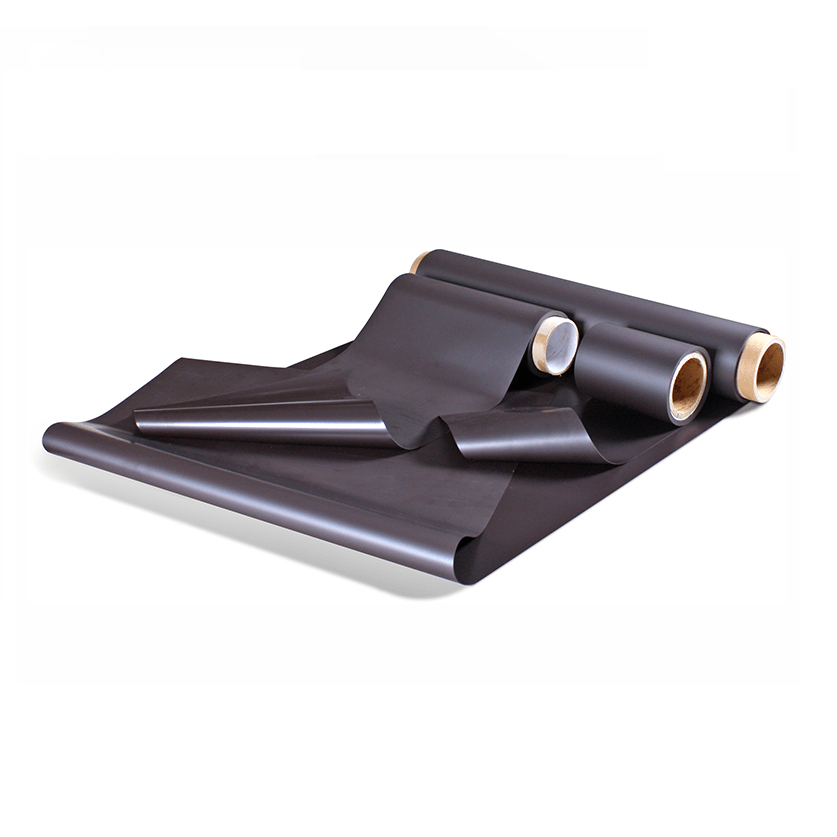

Flexible Magnets

Rubber Magnet & Flexible Magnets

Magnetic Properties

Notes: CMN-*(H/D or L)

CMN: Indicates that mould pressing, magnetic powder material is MQ patent product.

*: Indicates that (BH)max typical values is *MGOe.

H/D: Indicates that intrinsic coercive force is high.

L: Indicates that intrinsic coercive force is low.

Specification

- Material: isotropic, semi-isotropic, anisotropic

- Thickness: 0.2-10mm

- Width: Maximum 1524mm (60")

- Length: 15M/20M/30M, customized for large rolls

- Customizable size

Storage

- Processing environment: temperature (15-30℃), relative humidity (30-60%)

- Use environment: the daily temperature difference after Posting is within 40℃

- Storage conditions: sealed against light, temperature (15-35°C), relative humidity (20-70%)

- Shelf life: 12 months at room temperature, sealed and stored away from light, unused materials need to be resealed after opening the package

Printed Magnets

Printed magnets represent a cutting-edge solution, offering environmentally friendly and health-conscious printing materials. These magnetic materials are meticulously permanently magnetized, inherently corrosion-resistant, and possess special flexibility that allows for efficient cutting and post-processing. Our team of professionals carefully selects specialized printing substrates, including PVC, PET, PP, and more, and then skillfully laminates them onto Plain-Mag. This meticulous material combination is fully compatible with a range of printing methods, including digital printing, format printing, mounting, and cutting. We are committed to excellence in every aspect of the process, ensuring the utmost satisfaction of our valued customers.

Specification

- Material: Isotropic, Semi-isotropic, Anisotropic

- Standard Printing Surface Materials: White or colored PVC, white PET, white PP, paper, photographic paper, etc.

- Magnetic Adhesive Thickness: 0.2-1mm

- Width: Up to 1524 millimeters (60 inches)

- Length: 15M/20M/30M, custom lengths for large rolls available.

- Customizable Sizes Available

Storage

- Processing Environment: Temperature (15-30°C), Relative Humidity (30-60%)

- Usage Environment: Daily temperature variation within 40°C after application

- Storage Conditions: Sealed and protected from light, Temperature (15-35°C), Relative Humidity (20-70%)

- Shelf Life: 12 months at room temperature, stored sealed and away from light; unused materials opened from packaging need to be resealed for storage.

Application

The versatility of flexible magnets is evident in a wide range of applications, including promotional materials, decorative items, refrigerator magnets, toys, educational aids, and a variety of products. Additionally, due to their special magnetic properties, they have indispensable uses in micro motors, sensors, and various magnetic attachment solutions.

Flexible magnets represent a powerful combination of adaptability, durability, and magnetic performance, making them a reliable choice in many industrial and consumer environments. These characteristics together position injection-molded magnets as indispensable components in precision motion and sensing applications. Their versatility, coupled with their reliability and performance advantages, has led to extensive use in these demanding engineering fields.